Our Strengths

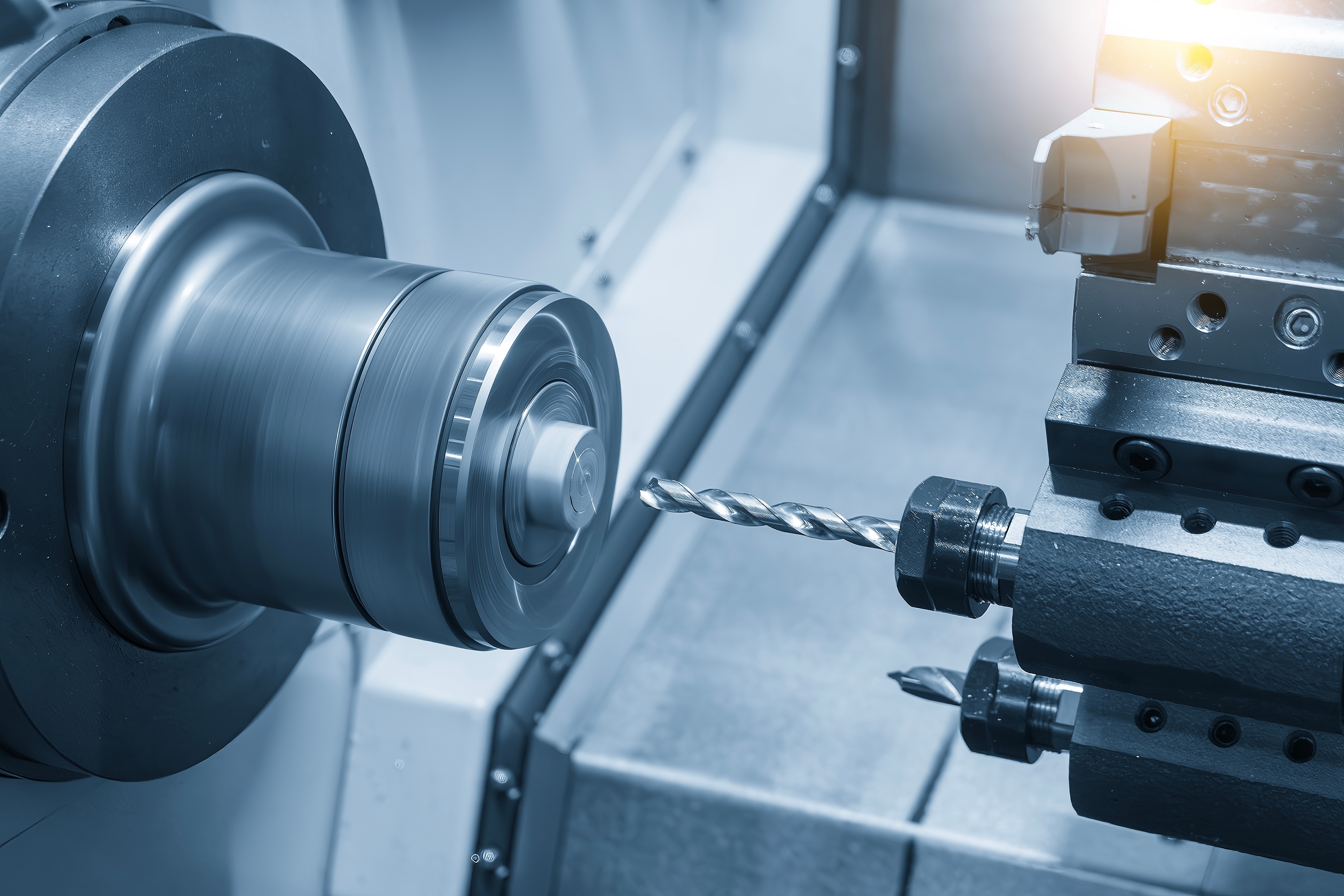

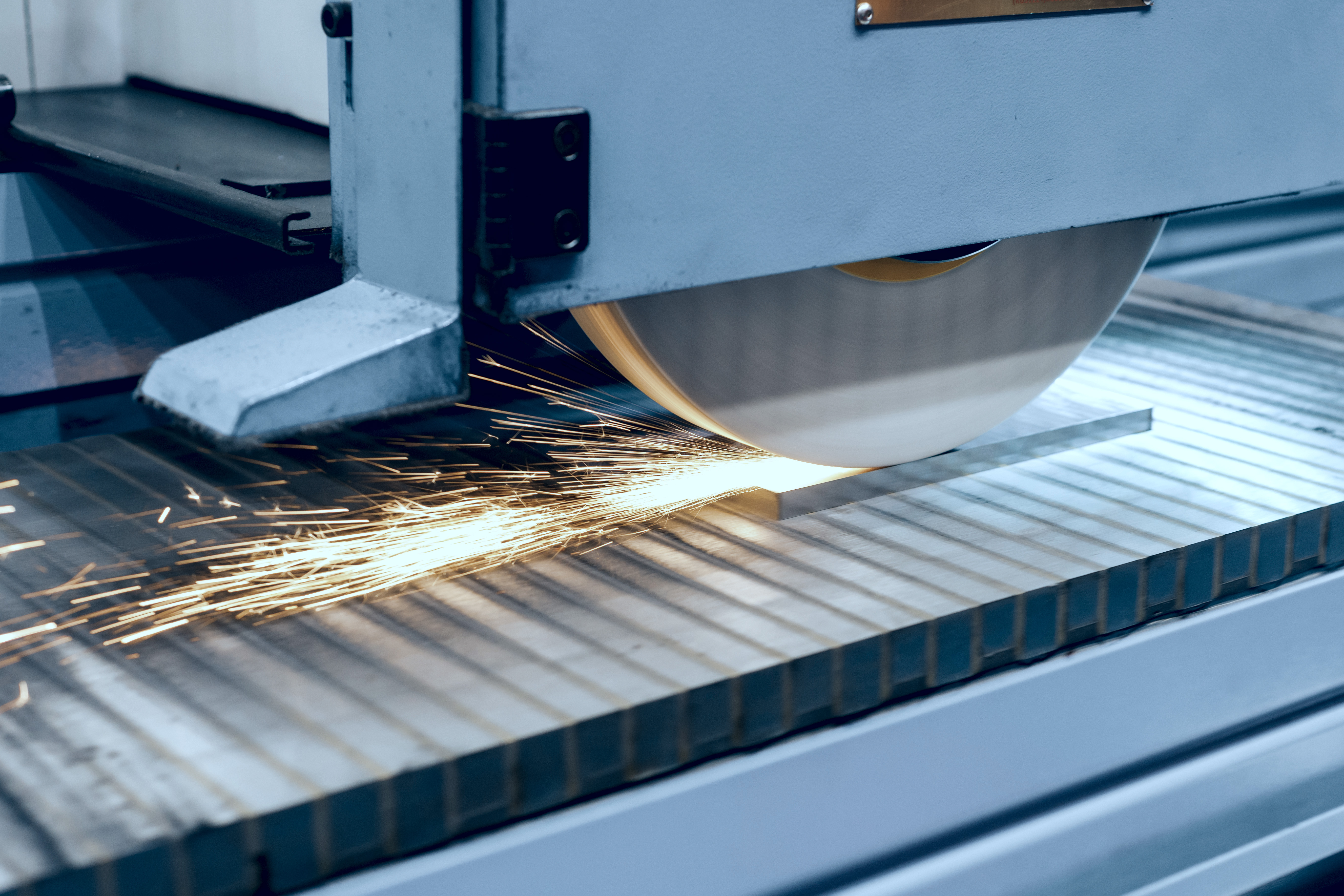

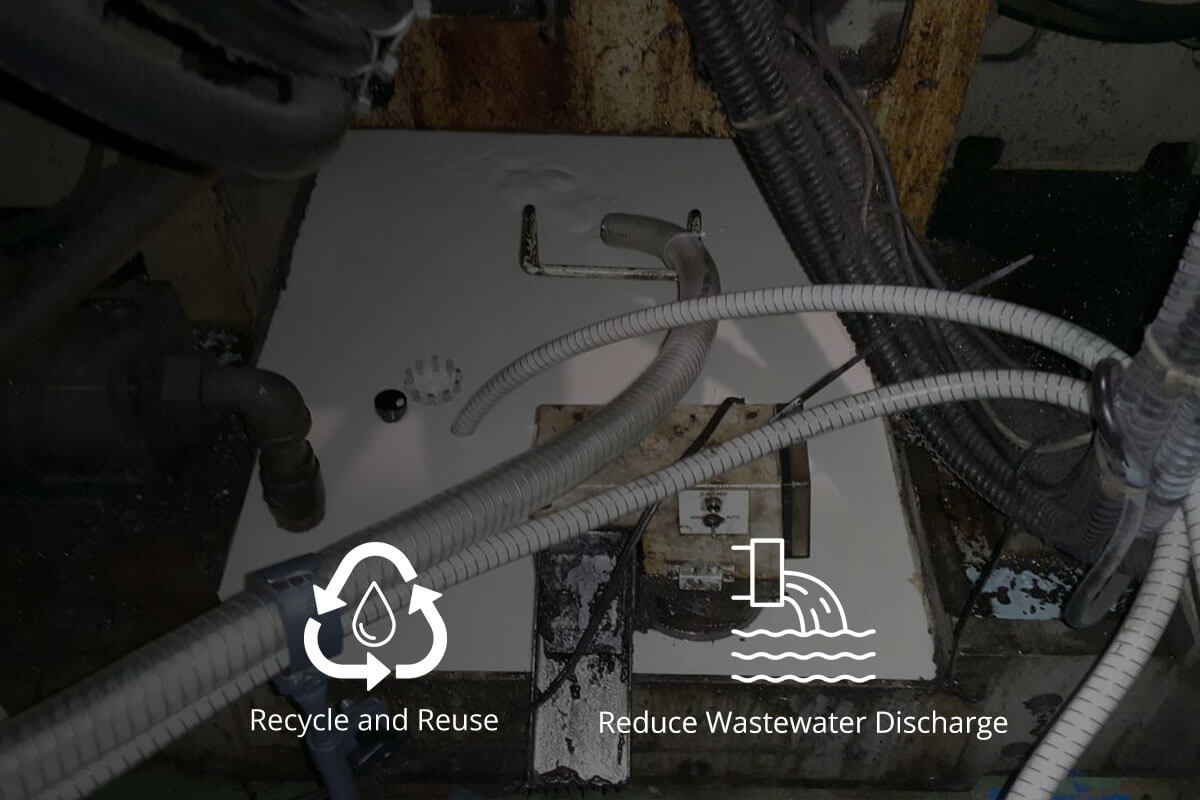

HC FENG team recognizes the challenges many manufacturers face with high wastewater treatment and recovery costs, as well as expenses for cutting fluid replacement. Therefore, we focus on the green industry, contributing to environmental improvement. We aim to address the issues of wastewater treatment, recovery costs, and cutting fluid replacement for manufacturers, achieving a balance between environmental sustainability and economic benefits.

.jpg)