Composite Oil-Water Separator

BEST-1 認證

認證Optimize with HC FENG Cutting Oil Filtration System

HC FENG’s BEST-1 is more than just a coolant oil skimmer. It’s a powerful, multifunctional solution combining cutting oil filtration, surface oil skimming, bacteria sterilization, and pH monitoring in one industrial-grade system. This innovative Cutting Oil Filtration System helps prevent rancidity, stabilize pH levels, extend fluid life, and reduce maintenance costs. Whether you're managing a standalone CNC machine or a centralized coolant tank, BEST-1 Cutting Coolant Purification System ensures your fluids stay clean and productive.

Why BEST-1 Outperforms Standard Coolant Oil Skimmers?

The addition of the ozone purifier to our Oil Water Separator Machine is a game-changer. Anaerobic bacteria growth in contaminated coolant is a common culprit behind fluid rancidity and unpleasant odors. Our decade-long experience in cutting oil skimming solutions has revealed that while many filtration systems remove tramp oil, they fail to address the rapid bacterial growth and micro contaminants. The ozone purifier in BEST-1 tackles these issues head-on, effectively extending coolant life and reducing the need for replacements.

Sustainable and CE-Certified Coolant Management

BEST-1 is designed to align with ESG sustainability goals and circular economy principles. By minimizing coolant replacement and reducing fluid waste, it not only saves costs but also contributes to greener manufacturing practices. The cutting oil filtration systems are fully CE-certified and ready for global applications.

If your operation requires a compact solution, we also offer the Mini Oil Skimmer (Best-Mini), ideal for tight spaces and lower-volume systems. For high-demand industrial environments, BEST-1 remains the superior choice.

Frequently Asked Questions - BEST-1 Oil Skimming & Purification System

A tramp oil skimmer removes floating oils that enter the coolant from machines, lubricants, or hydraulic systems. By eliminating this oil, the coolant stays cleaner and more stable, reducing the risk of bacterial growth, bad odors, and machining defects.

BEST-1 functions as a high-efficiency industrial oil skimmer, but it also offers built-in coolant purification, ozone sterilization, and pH monitoring, features that standard oil skimmers do not include.

While a basic CNC oil skimmer focuses only on surface tramp oil, BEST-1 provides a comprehensive solution, removing oil, sterilizing the coolant, and filtering out fine contaminants. It's a complete coolant recovery system.

Absolutely. BEST-1 is designed for both standalone machines and centralized coolant systems, making it ideal for a wide range of industrial applications.

Yes. BEST-1 is a suitable oil skimming system for grinding machines, EDM, CNC, milling, and other precision applications where maintaining clean, stable coolant is essential for surface quality and tool life.

Want to learn more about how BEST-1 enhances CNC Machining performance?

Maintenance frequency depends on usage volume and fluid contamination levels. However, we recommend inspecting the filter and sludge collection system weekly and performing a full cleaning monthly to ensure optimal coolant purification performance.

No special handling is required. The ozone module is fully integrated and maintenance-free under normal conditions. Regular inspection during scheduled maintenance is sufficient.

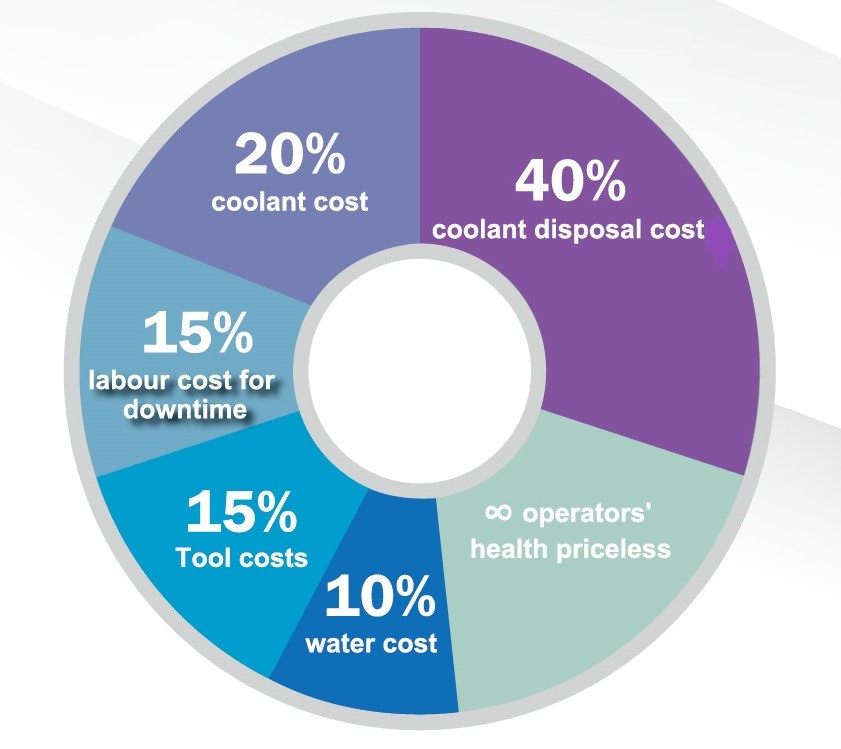

Definitely. By extending coolant life 2–3 times and reducing fluid degradation, BEST-1 cuts down both fluid purchase and disposal costs significantly.

- Filtering particulates max. 0.4mm

- Separating tramp oil in minimal moisture

- Sterilizing contaminants with ozone purifier

- Monitoring pH value

- No consumables

- Low maintenance

- Modularized parts and light weight

- Energy saving and green

- Step 1

- Oil collector – sucks in coolant and tramp oil from CNC machine tank

- Step 2

- Filter set - filters impurities and contaminants in the coolant

- Step 3

- Remove the slideway oil and foreign matter oil, achieve oil-water separation quickly and completely and reduce the water content

- Step 4

- Ozone purifier - eliminates bacteria, molds, or yeasts and purifies foul odor

- Step 5

- Control panel - automated settings to coordinate actions and intervals of suction, separation, skimming, and ozone generating process

- Step 6

- pH detection – automatically detects pH value

| Model | BEST-1 |

| Machine Size(L*W*H) | 520*410*880mm |

| Storing Capacity | 35L |

| N.W. | 45kg |

| Power | Single Phase.220V/110VAC 50/60HZ 0.042Kw |

| Power Consumption | consumption of 1 KWH of electricity in 24 hours |

| Suction Capacity | 10-30 Lit. /Minute |

| Capacity of lonic Generator | 500mg /hr (produce 500mg of ozone per hour) |