Centrifugal Magnetic Filter

FOODIE II 認證

認證Superior Filtration with HC FENG's Centrifugal Sludge Separator

HC FENG's centrifugal sludge separator, the FOODIE II, is a groundbreaking solution for precision machining environments where efficient separation of grinding sludge is critical. This advanced equipment revolutionizes the cleaning process by instantly extracting and discharging iron powder and dust without manual intervention, aligning with ESG sustainable development goals by promoting environmental friendliness and reducing carbon tariffs.

Why Choose Our Coolant Centrifugal Sludge Separator?

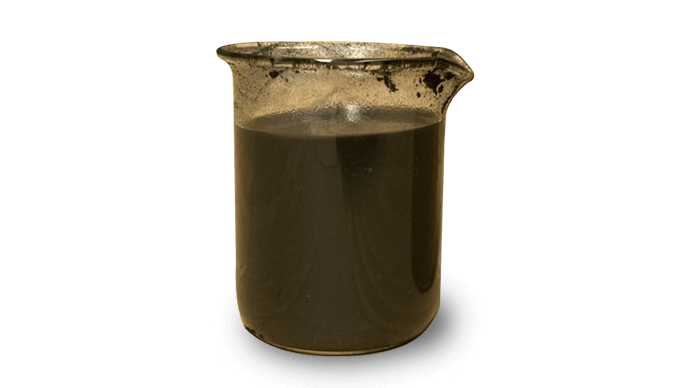

The FOODIE II separator is engineered with cutting-edge technology that guarantees superior performance. It features a 5000 Gauss Magnetic Separation that can filter down to 5 microns, effectively removing fine magnetic sludge such as cast iron powder. This eliminates the need for CNC machine downtime, significantly reducing labor and the frequency of coolant replacement. The separator is applicable to both neat oil and water-soluble coolants, making it versatile for various industrial applications. Additionally, its free-of-installation design ensures easy implementation in any workspace.

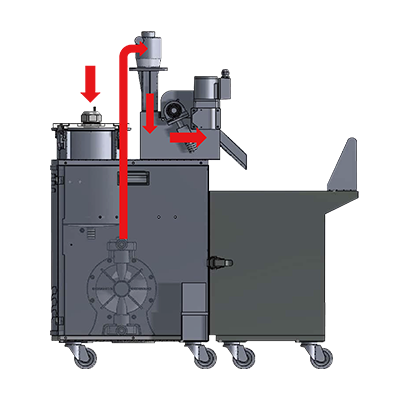

High-Efficiency Workflow

The FOODIE II operates through a meticulous workflow that enhances its filtration efficiency. It begins with the front coarse filter, which intercepts large particulates. The vortex dynamic filter follows, removing up to 90% of 10μm particles in water-soluble cutting fluid and 80% in oil-based cutting fluid, without the need for filter core replacement. The magnetic separator then efficiently separates magnetic metals, with an optional sludge cart for easy discharge and recycling of sludge and coolant.

Coolant Centrifugal Sludge Separator for Precision Machining Industries

HC FENG's centrifugal sludge separator is ideal for industries involved in precision machining, particularly those using grinding machines that produce fine particulate sludge. Its application extends to any sector requiring efficient coolant purification and sludge removal, making it a vital component in maintaining operational efficiency and sustainability in manufacturing processes.

By integrating the FOODIE II Coolant Centrifugal Sludge Separator into your workflow, you can achieve seamless sludge separation while supporting sustainable practices and reducing operational costs. Welcome to contact us, or check our case studies for further info!

- Needless of CNC machine downtime

- Extracts fine, magnetic sludge such as the cast iron powder

- Applicable to both neat oil and water-soluble coolants

- Centrifugal Filter

- 5200 Gauss Magnetic Separation

- Down to 5 microns filtration

- Free of installation

- Effectively reduces replacement and labor

- Front Coarse Filter

- Capacity of 5.5L, the bucket intercepts large particulates like metal chips.

- Vortex Dynamic Filter

- The filtration removes up to 90% of 10μm particles in water-soluble cutting fluid and 80% in oil-base cutting fluid. The cyclone effect eliminates the need to replace filter core; i.e., no consumable material needed. No bubbles are formed as it does not blend in air.

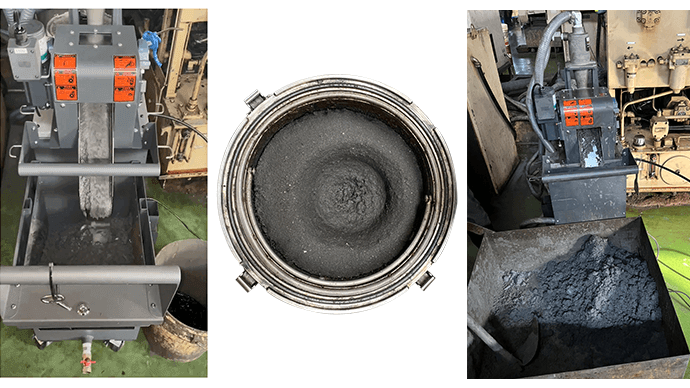

- Magnetic Separator

- The roller is power-driven to improve draining. Magnetic metals, such as iron, are separated from massive quantity of powders or particles, making the design perfect for highly magnetic separation in large flow rate.

The device generates extreme magnetic field up to 5,000 Gausses, significantly efficient in removing tiny metal particles.

- Sludge Cart (Optional)

- The sludge separated by the magnetic separator will be discharged directly into the sludge cart. The cart is able to dry the sludge and collect the coolant residual for recycling and reuse.

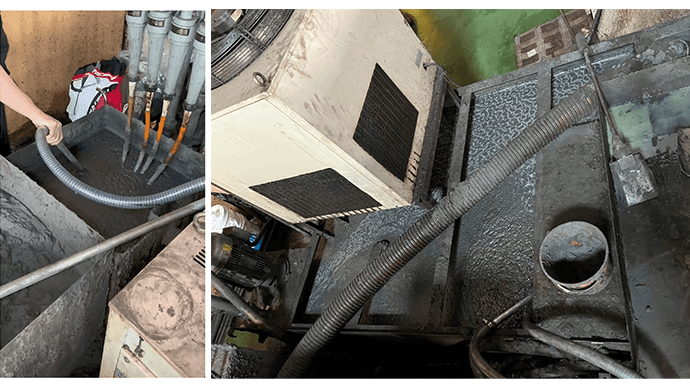

Chips and sludge are sucked in through the inlet pipe

Big particulates will be remained in the front filter

Finer particulates pass into the vortex dynamic filter

Sludge gets filtered and delivered to the magnetic separator

Magnetic separator discharges the extracted sludge

Clean coolant returns to the tank

Installation

This centrifugal magnetic separator is fully assembled and installed before delivering to you. You can simply unpack it, connect the power and activate its operation.

Maintenance

Regularly maintain the magnetic separator by cleaning the sludge residuals being accumulated around the roller.

All our equipment is smartly structured with an openable front door for users to maintain conveniently at any time.

| Model | FOODIE II |

| Machine Size(L*W*H) | 750*600*1250mm |

| Filter Capacity | 5.5L |

| Net Weight | 77kg |

| Max. Pump Capacity | 45 - 90 Lit. /Minute |

| Air Pressure | 0.5 Bar - 8.3 Bar (7.25 Psi - 120 Psi) |

| Voltage | Single Phase 110V/220V, 60/50Hz |