Automatic Coolant Refill and Mixing System

SHUNT 認證

認證Revolutionize Your Coolant Management with SHUNT

Still manually replenishing and adjusting cutting fluid concentration? In a world where time equates to money, model SHUNT, an automatic coolant refill system, is here to transform your operations. Overfilling cutting fluid can inflate costs, while underfilling leads to low concentration and rapid deterioration. Embrace the future with SHUNT, designed to fully automate the replenishing process, ensuring accurate cutting fluid concentration and eliminating the costly inaccuracies of manual labor.

Cutting-Edge Technology for Industry 4.0

As we advance towards Industry 4.0, automation becomes crucial. HC Feng auto coolant mixing and refill system integrates seamlessly into your factory's automation, ensuring that the often-overlooked cutting fluid management is no longer a bottleneck in your production. SHUNT purifies tap water through multiple filtration stages, including resin and activated carbon, and sterilizes it with ozone before mixing it with coolant concentrate at customer-specified concentrations using a premium Italian-made oil-water mixer.

Enhance Efficiency and Sustainability with SHUNT

Bid farewell to the days of the tedious task of mixing coolants. By automatically monitoring and replenishing coolant levels with precisely mixed solutions, SHUNT allows operators to focus on what they do best—keeping machines running and producing parts. This not only saves time and costs associated with manual fluid management but also aligns with ESG sustainable development goals, fostering an environmentally friendly and carbon-tariff-conscious solution.

Contact us for further info about SHUNT auto coolant mixing refill system!

- Filtration by 3 filters

- Impurity filtration from tap water -> resin filtration ->activated carbon filtration

- Sterilization by ozone

- The filtered tap water will be sterilized by ozone

- Oil-water mixer pump (Made in Italy)

- Precise mixing of 0~10% cutting fluid

- Stirring device

- The prepared cutting fluid is keeping stirred regularly to avoid becoming stagnant water

- Oil tank level meter

- 50 Gallon Barrel Low Level Detection

- Smart Flow System

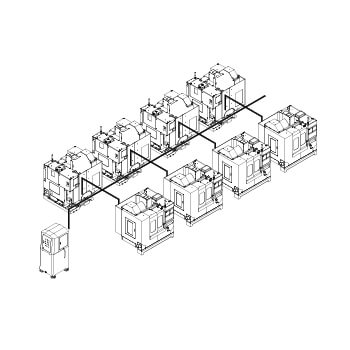

- The 3D view indicates that the supply line can be as long as 20m for multiple CNC machining centers.

| Model | SHUNT |

| Net weight | 183 kg |

| Dimension | (L*W*H) 900*1000*1610 mm |

| Tank capacity | tap water:125L / Mixer tank: 155L |

| Filter materials | 1-PP fiber; 2-resin; 3-activated carbon |

| Voltage | 220V.AC 50HZ |

| Power consumption | 500W / hr for continuous operation (the unit is set for indirect operation) |

| Ozone | 500mg/hr |

| Water inflow | 10L/min |

| Fluid outflow | 40L /min; 80L/min. Max |

| Oil-water mixer pump production | 0.17 ~50L /min. (10-3000L/hr) |

- Flowmeter

- Fixed flow: 1/2” (15A): 60L/min; 3/4” (20A): 100L/min

No-cutting flow: 0.5L/min (variable, initial value)

- Concentration meter

- Detection by refractive index

Rated concentration range: Brix: 0%~20% (nD: 1.32500~1.37000) - Range displayed: Brix: 0%~25%

Applicable fluids: noncorrosive water-based solutions (water-soluble coolant, mold release agent, etc.)

- Display screen

- QVGA 2.0 color LED display with status indicators

Display refresh cycle: ~10 second/refresh

Network supported: IQ-Link

Data storage: USB 2.0, storage up to a year

- Level detector(Made in Japan)

- Detection Range: 1500mm

.jpg)