How BEST-1 Oil Skimmer Delivers Measurable Cost Savings in Coolant Management

In metalworking and CNC machining environments, coolant management is one of the most underestimated cost drivers. While many factories focus on tooling or machine uptime, coolant contamination caused by tramp oil quietly increases operating expenses through frequent tank cleaning, coolant replacement, and labor-intensive maintenance.

The Hidden Cost Problem in Coolant Systems

Every machining facility experiences tramp oil contamination. Lubricating oils from guideways, hydraulic systems, and spindles inevitably migrate into the coolant tank during normal operation. Over time, this oil layer prevents proper oxygen exchange, accelerates bacterial growth, and causes coolant to break down far earlier than its theoretical service life.

As coolant quality declines, operators begin to experience odor issues, unstable cutting performance, and increased machine cleaning requirements. What starts as a chemical imbalance quickly turns into a recurring operational expense that affects maintenance schedules, labor planning, and waste treatment costs.

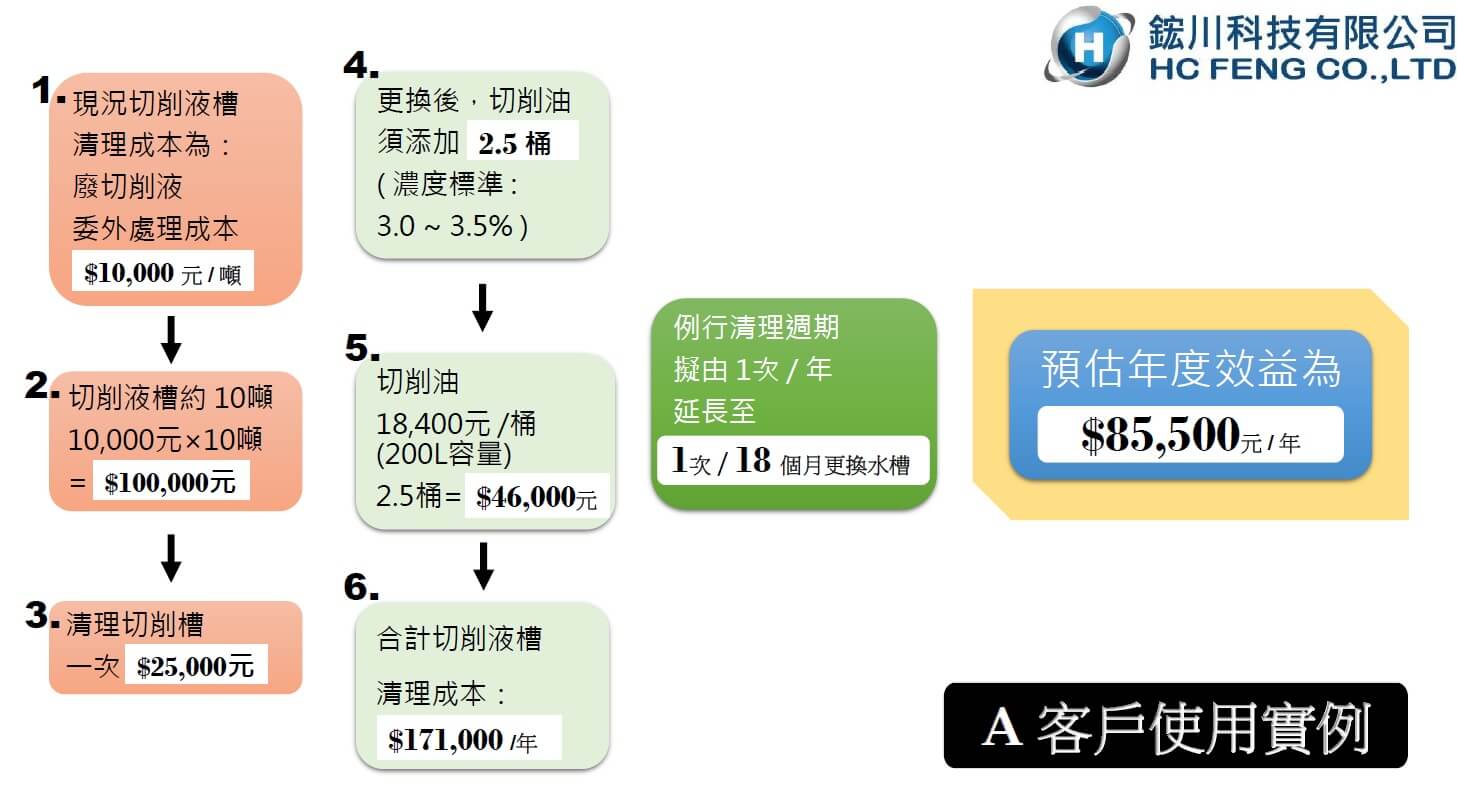

Cost Structure Before Installing an Oil Skimmer

To understand the financial impact, consider a machining facility operating ten machines with a combined coolant volume of approximately ten tons. Before any coolant purification equipment was introduced, the factory followed a standard annual cleaning and replacement cycle.

| Cost Item | Description | Annual Cost (USD) |

| Coolant tank cleaning & waste recycling | USD 400 per ton × 10 tons | 4,000 |

| Labor cost | Maintenance personnel | 900 |

| New cutting coolant | 2–3 barrels per refill | 1,600 |

| Total annual cost | 6,500 |

Although these expenses were accepted as “normal operating costs,” they provided no added value to production. They merely restored the system to its original condition.

How an BEST-1 Changes the Equation

An industrial oil skimmer continuously removes floating tramp oil from the coolant surface before oxidation and bacterial growth accelerate. This stabilizes coolant chemistry and dramatically slows degradation.

When the BEST-1 cutting coolant purification system was installed:

- Tramp oil was removed continuously

- Coolant quality remained stable for longer periods

- Manual intervention was minimized

Rather than reacting to coolant failure, the factory shifted to a preventive approach where contamination was addressed before it became a problem.

Cost Reduction After Installing BEST-1 Coolant Oil Skimmer

After the oil skimmer was implemented, the coolant tank no longer required annual cleaning. The service interval was extended to approximately once every one and a half years. This single change reduced the annualized cost of coolant cleaning, disposal, and refilling.

Based on actual operating data, the factory achieved an annual cost reduction of USD 2,168, while maintaining the same production output and machine utilization. Importantly, this saving was achieved without modifying machine tools, cutting parameters, or coolant formulations.

This reduction is achieved without changing machines, tooling, or cutting parameters—only by improving coolant hygiene.

Why These Savings Scale with Production Size

The financial benefit of oil skimming becomes more pronounced as machine count and coolant volume increase. Facilities operating multiple CNC machines experience compounding savings because extended coolant life reduces downtime, minimizes labor disruption, and stabilizes machining quality over long production runs.

Beyond direct cost savings, operators reported improved shop-floor conditions, fewer odor complaints, and more predictable maintenance planning. These indirect benefits further strengthen the return on investment, even though they are harder to quantify.

BEST-1 Oil Skimmer as a Strategic Coolant Management Tool

For many manufacturers, coolant maintenance has traditionally been viewed as an unavoidable expense. However, real-world data shows that controlling tramp oil transforms coolant systems from a recurring cost center into a manageable, optimized process.

BEST-1 is not simply an auxiliary device. It is a practical, data-backed solution that reduces waste, extends coolant life, and delivers measurable financial returns year after year.