Coolant Purification Solution for Die Casting

- Filter separators is the solutions to process fluids in die casting and forging industries.

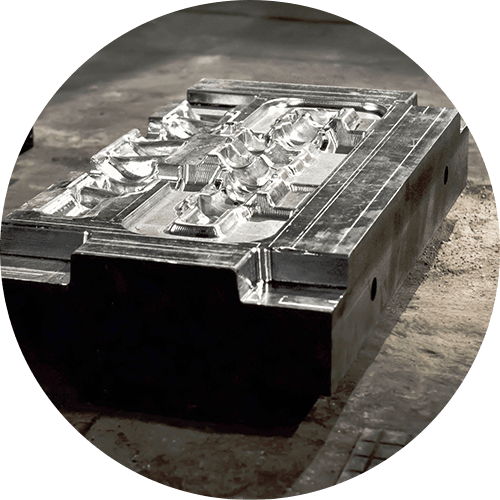

- The Die casting is a machining process in which molten metal is injected into a mold under high pressure and hardened. Aluminum alloy made auto parts, bicycle spare parts, vehicle components and auto light are mostly made by die casting. It is one of popular metal processing methods. Further, the wastes and scrap materials from the machining are not much as they can be recycled in large part. Forging is to heat, deform, and have metal pieces finished by pressing materials into designed customized shapes. Forging cases are pliers, hammers, wrenches and hand tools, as well as sockets, hooks, bolts and screws.

- The die casting and forging industries always concern a lot about product quality and productivities together with contamination from waste machining fluids and tramp oil, too.

What can the BEST-1 Coolant Purification Equipment do for the above industries in the plants?

The ordinary oil-water separators sold on the current markets, no matter they are belt types, disc types, or chain types, have only the function of separating oil and water. Tramp oil contains a lot of water still that is not so effectively. The Oil Skimmer of BEST-1 can gather and remove the waste oil effectively and maintain the concentration of the coolant liquids. Besides the cutting liquids contain a lot of bacteria which can cause the cutting fluids deteriorated and contaminated, and acidized. It causes skin allergies and other problems.

The Technology of BEST-1 cutting fluid purification and refreshing equipment designed by HC FENG has the functions of filtering impurities, high efficient oil-water separation, and Ozone device for sterilization and deodorization. It helps to extend tool life that can improve machining accuracy. It reduces costs and time in cleaning sumps by labors and breaking productions during machine downtime as well.

How do we do after service?

HC's filtration equipment is a modular design. It is easy to do part replacements. The filter is made of stainless steel, just clean it with water or blow out the filtered chips by the air blow gun attached.

When installing the BEST-1 cutting fluid purification equipment, the cutting fluid together with impurities and tramp oil will be sucked into inner system first. Then it goes through a stainless steel filter to filter out impurities such as iron debris and metal chips. After then it goes to oil-water skimmer to remove dirty oil. Finally, the Ozone device is used for sterilization and deodorization. The purified cutting fluids are eventually returned to the CNC water tank for reuse. The automatic procedures of BEST-1 equipment are all set up by a smart control panel completely. Users can start working immediately after installing it. You would manage and control the scheduling time by re-setting the panel according to your CNC production plan practically, if needed.

Installing HC's Coolant purification system ensures purifying and filtration of tramp oil, metal chips from the processing liquids effectively. Our purification technology is not only used for removing tramp oils, impurities and metal chips, but also preventing the cutting liquid acidification, which reduces the risk of bacterial contamination and odors. Unique Ozone device is especially designed for sterilizing bacteria from used coolant and keeping pH value and smells in the oiled liquids. pH meter for pH detection is optional . Detection of pH value always reminds you the quality of the cutting coolant.

What would the benefits of our coolant filtration equipment bring you?

Despite people believe that purifying processed coolant saves money, few plant managers have actually calculated the cost savings of keeping clean coolant in their machines. And the cost savings are considerable.

Cost savings stem from the following improvements: A good coolant is regularly maintained with a high-efficient oil skimmer|separator unit which can run in the sump at least for a year before the coolant should be replaced with new one. If you don't have an oil skimmer or use an inefficient belt or disc oil skimmer, you must change the coolant every two months or four times a year. As a result of this, annual coolant purchase and disposal costs can be reduced by 3 replacements, e.g. 20% of coolant replacements together with 40% of coolant fluids disposal costs, through efficient coolant maintenance. Meanwhile, the costs of labor and machine downtime during coolant changes can be also reduced by 15% annually.

Running with purified and filtered coolant significantly reduces tooling abrasion comparing to running with dirty coolant. The benefits of cleaning and filtering coolant with our products are conservatively estimated to save 10% on tooling costs.

How does HC FENG's Filtration and Separation equipment improve processing workshop?

The in-shop harsh environment has long been an issue, such as odors, bacteria, harmful chemical/oil mist, etc. from deteriorated coolant which causes operators allergies and dermatitis. Therefore, to maintain the cleanliness of coolant fluids in the tanks is vital to plants. However, while environmental concerns remain important, most plant managers recognize that maintaining clean coolant in their machines is critical. How to run a factory efficiently and profitably, in the current difficult economic environment? Generally if a machine tool runs just as well with dirty coolant as it does with clean coolant, no one would change the coolant to the new. Using dirty coolant day by day harms labors and environment. In order to balance cost and environment, our products would be the answer.

As a quality manufacturer in this field, it's our duty to safeguard your health and improve the environment with our good products.