The Hidden Risks of Cutting Fluid Deterioration: 6 Warning Signs You Should Know

Cutting fluid is more than just a lubricant—it’s essential for maintaining machining accuracy, extending equipment life, and protecting worker health. Yet, many workshops overlook early signs of deterioration until problems become costly. Recognizing these warning signs early can prevent production delays, reduce maintenance costs, and ensure a safer working environment.

Why Cutting Fluid Is Crucial in Metalworking

Cutting fluid (also called coolant) serves multiple purposes in metalworking:

- Lubrication: Reduces friction between cutting tools and workpieces.

- Cooling: Prevents overheating that can damage tools and materials.

- Chip Removal: Flushes away metal particles to maintain clean machining.

- Health & Safety: Minimizes airborne oil mist and harmful bacterial growth.

When cutting fluid degrades, these benefits diminish. Poor fluid quality can cause machining inaccuracies, increased tool wear, equipment corrosion, and potential health hazards.

Six Major Warning Signs of Deteriorating Cutting Fluid

Spotting even one of these signs indicates your cutting fluid may already be harming your shop’s efficiency and safety:

-

Unpleasant Odor: A Sign of Bacterial Growth

A foul or sour smell often indicates microbial contamination. This can accelerate corrosion, reduce coolant lifespan, and create unhealthy air quality for operators.

Quick Fix: Treat with biocides or replace the fluid to prevent further bacterial proliferation. -

Darkened or Cloudy Appearance

Clean cutting fluid is usually clear or slightly colored. Darkening or cloudiness signals chemical breakdown or suspended debris.

Quick Fix: Filter the fluid regularly and monitor for early discoloration. -

Thickened Texture or Poor Emulsification

Fluid that no longer mixes well or has separated layers indicates a loss of emulsifiers. This reduces lubrication efficiency, increasing tool wear and machining heat.

Quick Fix: Re-emulsify or replace the fluid to restore proper viscosity. -

Acidification and Dropping pH Levels

A decreasing pH points to acid formation, which can corrode machines, damage workpieces, and shorten fluid life.

Quick Fix: Test pH frequently and adjust with neutralizing additives, or replace if necessary. -

Excessive Oil Mist Production

Excess mist can harm worker respiratory health and deposit on machinery, causing cleaning and maintenance challenges.

Quick Fix: Improve ventilation, maintain fluid concentration, and use mist-reducing additives. -

Decline in Machining Performance

Slower cutting speeds, rough finishes, or frequent tool replacement are signs that fluid performance is failing.

Quick Fix: Check fluid concentration, filtration, and consider a full replacement to restore machining accuracy.

How Cutting Fluid Deterioration Affects You

Ignoring deteriorating cutting fluid can lead to:

- Increased machine downtime and maintenance costs

- Higher tooling expenses due to accelerated wear

- Reduced product quality and precision

- Worker health risks, including respiratory issues and skin irritation

Proactive fluid management ensures production efficiency and a safer workplace.

Practical Steps to Fix Cutting Fluid Issues

- Regular Testing: Monitor pH, concentration, and microbial activity weekly to catch early signs of deterioration.

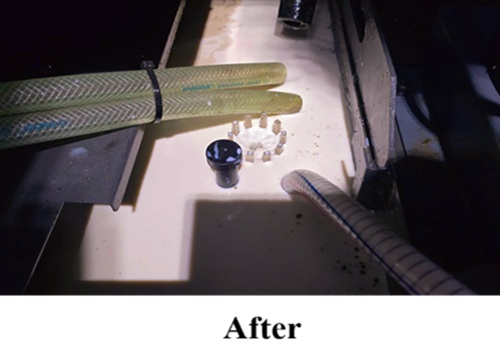

- Filtration & Cleaning: Continuously remove metal chips, debris, and tramp oil. Using our BEST-1 Cutting Oil Filtration System(Coolant Oil Skimmer) can efficiently separate oil and impurities from your cutting fluid, maintaining its performance and extending fluid life.

- Additives & Biocides: Prevent bacterial growth and chemical breakdown to keep your fluid stable and safe for operators.

- Scheduled Replacement: Change fluids according to manufacturer guidelines to ensure machining accuracy and equipment protection.

- Operator Training: Educate your team to recognize warning signs early and take corrective actions before production quality is compromised.

Protect Your Machines and Workforce Today

Don’t wait for a problem to escalate. Now’s the moment to reinforce your cutting fluid management before the situation gets worse. Keep your shop running smoothly, improve machining accuracy, and safeguard your team’s health. Contact us for further info!